Application of forging technology in light metals

Author:

Hou

Jul. 09, 2025

123

0

0

With the progress of science and technology and the development of society, all walks of life have put forward higher and higher requirements for the preparation of materials. In important fields such as aerospace, automobiles, and energy, lightweight alloys such as titanium alloys, aluminum alloys, and magnesium alloys have been increasingly used.

Since the invention of the free forging hydraulic press in the 18th century, with the continuous enrichment and improvement of the theory of metal plastic forming, forging has become an advanced manufacturing method. In the machinery industry, some parts with high requirements for mechanical properties are mostly produced by forging technology. The production of large forgings is the embodiment of the country's comprehensive strength, and large and complex structural parts such as domestic C919/C929 aircraft integral frames, submarine shell structures, and large launch vehicle shells all need to rely on forging technology to complete. Since 2010, China's annual forging production has exceeded 10 million tons, but China's forging output accounts for a relatively low proportion of precision forgings, only 9%, significantly behind Japan's 36% and Germany's 37%, and China's precision forgings are mostly small parts, with a single variety. At the end of the 20th century, the United States, Japan and Europe have formulated medium and long-term development plans for forging technology. In 2015, "Made in China 2025" also put forward digital and intelligent requirements for advanced manufacturing, including forging.This paper will introduce the current forging process and the application of forging technology in lightweight alloy parts such as titanium alloy, aluminum alloy and magnesium alloy, and look forward to the digital application and future development trend of forging. Forging is a processing method that applies pressure to the metal blank and makes it plastically deformed to obtain certain mechanical properties and meet the dimensional requirements. According to the different production processes, the forging process can be classified as: open forging, module forging and special forging. According to the forging temperature, the forging technology can be classified as: hot forging, warm forging and cold forging. At present, a near-net shape technology, that is, precision forging technology, has been more and more used, which mainly includes: isothermal forging, multi-directional forging, hot die forging and cast-forging composite forming technology.

Open forging has low requirements for equipment, simple operation and low cost. Open forging is divided into manual open forging and machine free forging. Manual free forging relies on manpower and tools to forge blanks, mainly producing small parts. According to the different types of equipment used, machine free forging is divided into forging hammer free forging and hydraulic press free forging, but the production efficiency and material utilization rate of open forging are low, and the consistency of products is poor.In the conventional forging process, the heat of the blank is dissipated, and the temperature of the blank close to the mold decreases, resulting in an increase in deformation resistance and a decrease in the plastic deformation ability of the material. On the one hand, higher requirements are put forward for forging equipment, and on the other hand, forgings are prone to cracking and other defects, resulting in waste of raw materials. Isothermal forging is an emerging technology in which the temperature of the die and blank is kept consistent during the forging process, and then formed by a lower deformation rate. During the deformation process, the blank is in a state of dynamic recrystallization and softening, so that the deformation resistance is low, and the microstructure obtained is also excellent. Isothermal forging also has high requirements for forging equipment and dies: forging equipment needs to have good control accuracy to ensure a low deformation rate; The die material needs to maintain sufficient strength and mechanical stability at the forging temperature, and it must not be oxidized.1.3 Multi-directional forgingMulti-directional forging technology is a large plastic deformation process, in which the load loading direction of the forging is constantly changed during the deformation process, that is, the blank is forged in multiple passes in different directions. Generally speaking, the multi-directional forging temperature is often lower than the recrystallization temperature, and with the continuous change of forging direction, the internal "dead zone" of the forging billet is eliminated, and the microstructure with small, uniform and weak anisotropy is obtained. The grain refinement mechanism in the multi-directional forging process is mainly due to the induction of deformation and thermomechanical deformation. The multi-directional forging technology does not have high requirements for equipment and strong applicability, and can be used to prepare bulk materials with a large volume.Research on titanium alloy forging Titanium is known as the "third metal" after steel and aluminum, titanium and titanium alloys have good performance (high specific strength, excellent corrosion resistance, high temperature resistance, non-magnetic, etc.), and have been widely used in aerospace, automotive industry, chemical industry, energy and other industries. The cold working forming of titanium alloy is relatively difficult to achieve, and the preparation of titanium alloy parts is usually carried out by hot working forming. The forging of titanium alloy needs to be realized within a narrow temperature window, because when the temperature is too low, the titanium alloy is prone to defects such as cracks during deformation, and when the temperature is too high, it faces the problem of coarse structure. The "β forging" of titanium alloys has the disadvantage of poor plasticity, which can be improved by appropriate heat treatment and cooling control processes. The "α+β two-phase forging" of titanium alloy has the disadvantages of low breaking strength and poor toughness, and the machining allowance is large.

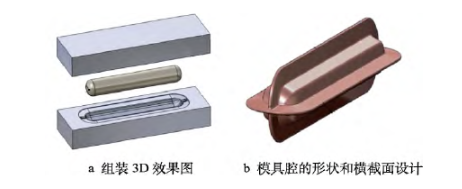

At present, researchers have done a lot of research on the forging technology of titanium alloys. Feng Zhaohui et al. used the constant load precision die forging technology of mechanical press to produce TC4 titanium alloy full hip joint. After forging in the two-phase zone, the hip joint can be implanted into the human body without machining and only after surface finishing, and the mechanical properties meet the American medical standard (ASTM F620). High-quality artificial joints produced using precision forging technology have better forging streamlines, performance, and lower adverse effects on the human body. Regarding titanium alloy powder forming, Li Ting has reported a new titanium alloy processing technology - titanium alloy powder is first made into billets, and then nearly net shape is carried out through precision forging. Zhao et al. calculated the ideal hot working interval of Ti-17 powder briquettes by thermal simulation compression test and thermal processing diagram. After isothermal forging, the original coarse grains of Ti-17 are broken and decomposed to form a large number of ultra-fine recrystallized grains and evenly distributed in the β matrix, which greatly improves the corresponding mechanical properties. Luo et al. studied the influence of friction on the microstructure of titanium alloy forgings, and found that when the lubrication conditions were improved, the lamellar α+β structure was less affected, while the content of α phase increased significantly, the content of β phase decreased, and the uniformity of distribution of α phase and β phase decreased. Zhang et al. precision forged the Ti-6Al-4V alloy prepared by selective laser melting (SLM) process, and the content of β phases in the microstructure increased after forging. It was also found that the high strain rate and large deformation could reduce the microporosity by up to 74.6% and improve the fatigue properties, while the microhardness difference between the horizontal and vertical sections of the alloy was reduced and the anisotropy was optimized after forging and water quenching. In order to improve the mechanical properties of the sintered TiBw/TA15 composites with network architecture, Zhang et al. conducted multi-directional forging on them, and found that the ultimate tensile strength and maximum elongation of the forged materials showed good uniformity, and were increased by 8.4% and 160%, respectively, compared with the sintered state. Among titanium-based alloys, TiAl alloy has attracted the attention of many researchers due to its low density, high specific strength, excellent resistance to high-temperature oxidation and creep, but because its matrix is mainly γ-TiAl (face-centered tetragonal) and α2-Ti3Al (close-packed hexagonal) phases, its processing performance is poor, and it shows sensitivity to temperature and strain rate. The thermomechanical processing of TiAl alloy mainly includes forging, extrusion and rolling, among which the forging methods mainly include isothermal forging and package forging. Zhang Wei et al. combined Deform-3D and thermophysical simulations to simulate and verify the stress, strain and temperature field of TiAl alloy, and successfully prepared TiAl alloy discs with a diameter greater than 150 mm. Tang et al. compared the microstructure and oxidation properties of TiAlNbCr alloys in cast and isothermal forged states, and found that the microstructure of TiAlNbCr alloys was significantly refined after isothermal forging, and the forged alloys inhibited the diffusion of O due to their smaller grain size and microstructure uniformity, and had better oxidation resistance than those in as-cast form. Li et al. found that the near-γ phase microstructure of TiAl alloy was transformed into a two-phase structure after single-axis forging and multi-axis forging. After multi-axis forging, the microstructure underwent obvious re-repeated dynamic recrystallization, and showed good mechanical properties: at 750 °C, the yield strength, tensile strength and elongation were 623 MPa, 697 MPa, 4.5%, and 900 °C/0.001s-1, respectively, the yield showed superplasticity, and the elongation reached 173%. At present, TiAl alloy forgings have been used in aero engine compressor blades.Research on aluminum alloy forging In automotive and aerospace applications, there is a growing demand for lightweighting to improve fuel efficiency and reduce greenhouse gas emissions. Aluminum alloys are widely used in the aerospace and automotive industries due to their high specific strength, good corrosion resistance and excellent machinability. Aluminum alloy has good plasticity, can be used for the forming of complex structural parts, the machining allowance is small, significantly improve the material utilization rate and reduce costs. Kumer et al. strengthened the Al6082 alloy with small strain through multiaxial forging technology, and the forged alloy exhibited good strength and plasticity, mainly due to the formation of ultrafine grains with a size of about 411 nm, the emergence of a large number of dynamic recrystallized grains, and the precipitation of "β" phases. In view of the problem that the material utilization rate of 2Al2 aluminum alloy in a certain type of weapon is not high due to direct cutting and preparation, Wang Ziqi et al. used the combination of upsetting and reverse extrusion to carry out precision forming, so that the quality of the blank was reduced from 550g to 190g, which greatly improved the utilization efficiency of the material. Zhang Xiang et al. used finite elements to study the process parameters (deformation velocity, deformation temperature, deformation pass, etc.) that affect the multi-directional forging process of 6061 aluminum alloy, and found that the metal in the core region of the aluminum alloy billet presents a "figure-eight" flow characteristic during the forging process, and the deformation uniformity increases with the increase of forging passes. The finite element simulation results are in good agreement with the actual test results, and the accuracy is verified. Mathew et al. studied the semi-solid forging of Al-4.5Cu and Al-4.5Cu-5TiB2 (mass fraction), and the EBSD and nanoindentation studies showed that the semi-solid forging led to dynamic recrystallization and refinement of the grains in the composites, resulting in a significant increase in the hardness and elastic modulus of the alloy. Zhou Yujie et al. carried out multi-directional forging and multi-directional forging + heat treatment of 2014 aluminum alloy respectively, and found that the microstructure of 2014 aluminum alloy was refined after different treatments, and the tensile strength was 538.6 MPa and 527.3 MPa, respectively, and the anti-sliding wear performance of the material was significantly improved. Yu Rui et al. used Deform software to numerically simulate the isothermal forging process of the 7075 aluminum alloy differential housing, and found that the maximum value of equivalent stress appeared at the abrupt transition site, and determined that the optimal forging temperature was 425 °C. Yu Yongxin et al. used the composite forging process of isothermal multi-directional forging + isothermal die forging to prepare 2A14 aluminum alloy wheels, and found that with the increase of forging temperature, the deformation mechanism changed from dynamic softening to dynamic recrystallization, and the optimal deformation process parameters were obtained: isothermal multi-directional forging was carried out at 450 °C for 6 times, followed by isothermal die forging at 460 °C, and the tensile strength of the hub reached 491 MPa and the elongation reached 12%. Tilak et al. studied the effects of different forging temperatures and strains on the internal particle morphology, clearance ratio, hardness and so on of powder sintered Al7075 alloy, and found that the oxide layer during the forging process could be effectively removed under 0.8Tm and 0.92 strain. Shin et al. evaluated the malleability of Al-6Mg alloy extrusion rods at room temperature, and designed an octagonal rod die for a biaxial alternating forging system, as shown in Figure 1. The tensile strength of the forgings increases significantly with the increase of the number of forgings, and the formation of twins and dislocation clusters is shown in the microstructure.

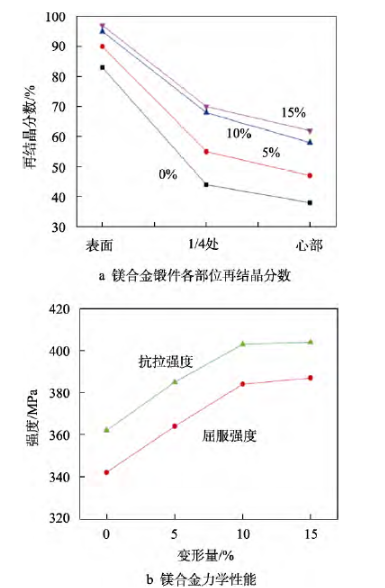

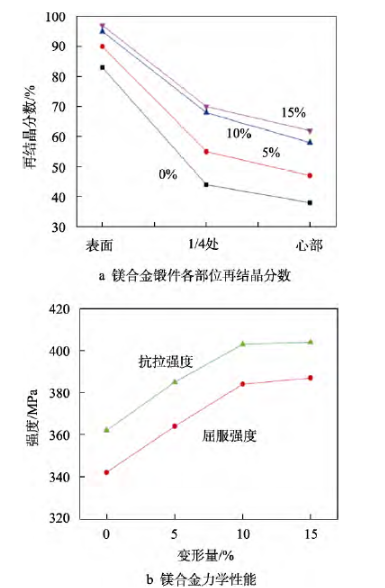

Magnesium alloy forging research Magnesium alloy is the lightest metal structural material (about 25% of steel, 63% of aluminum alloy), with good thermal conductivity, shock absorption ability, electromagnetic shielding performance, easy recycling and many other advantages, known as the 21st century new green metal structural materials, but the processing and preparation of magnesium alloy is limited by its poor plasticity. The magnesium alloy is a close-packed hexagonal structure, and it is difficult to deform with few movable slip systems when deformed at room temperature. When deformed at high temperatures, it faces the problems of oxidation and grain coarsening. At present, most magnesium alloy parts are die-casting, with some defects such as shrinkage porosity and porosity, and the grain structure is relatively coarse, and the mechanical properties are poor.In order to optimize the structure and achieve lightweight while ensuring the mechanical properties of magnesium alloys, researchers have done a lot of research on the forging and forming of magnesium alloys. Quan Gaofeng et al. used the isothermal superplastic extrusion die forging process to prepare magnesium alloy wheels, and after die forging and heat treatment, the mechanical properties were higher than those of cast magnesium alloy and cast aluminum alloy wheels (16% energy saving compared with aluminum alloy wheels), and showed good fatigue resistance and excellent adaptability to surface treatment technology. Xu Wenchen et al. used a combination of simulation and experiment to study the preparation of thin-belly high-ribbed scaffold components by isothermal forging of Mg-9Gd-3Y-0.6Zn-0.5Zr alloy, and found that increasing the fillet of the side wall rib and web junction and adding movable damping block can eliminate the defects caused by insufficient pumping. Li Li et al. used isothermal forging and extrusion composite forming technology to prepare Mg-9Gd-4Y-0.4Zr alloy thin-walled cone tubes, and optimized the design of three kinds of forging billets with different tapers. Han Xiuzhu et al. used Deform software to optimize the design of high-strength and toughness rare earth magnesium alloy stiff plate components, so that the metal flowed along the wedge-shaped surface and the reinforcement was filled at the same time, and the tensile strength and elongation were 371MPa and 4.07%, respectively.The microstructure of magnesium alloy in the forging process is also affected by the forging method and forging process, which in turn affects the physical properties. Wu Yuanzhi et al. studied the effects of different forging methods on the microstructure and mechanical properties of ZK21 magnesium alloy, and found that changing the forging direction can increase the cumulative strain of the alloy. In unidirectional forging, the microstructure is uneven, and the ultrafine and coarse recrystallized microstructures with an average grain size of 0.3 μm and the fine recrystallized grains with an average size of 0.3 μm are obtained in the two-way forging and three-way forging, respectively, and both exhibit good mechanical properties. Wang et al. studied the Mg-5Zn-1Y-0.6Zr alloy by using cavity liquid die forging technology, and found that after cavity liquid forging, the dendrites in the microstructure were elongated along the deformation direction, and the second phase particles were broken and decomposed. It has the highest tensile strength of 351.5 MPa when deformed at 350°C, and the best elongation of 7.15% when deformed at 450°C. Park et al. studied the effect of pre-cooled forging on the microstructure and mechanical properties of extruded Mg-8Sn-1Al-1Zn alloy, and found that within 10% of the deformation, the proportion fraction of the recrystallization region in the microstructure and the tensile properties gradually increased with the increase of pre-cooled forging deformation, as shown in Fig. 2.

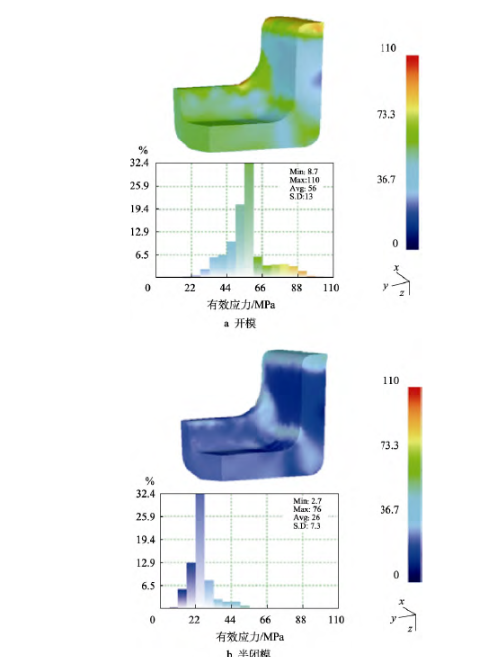

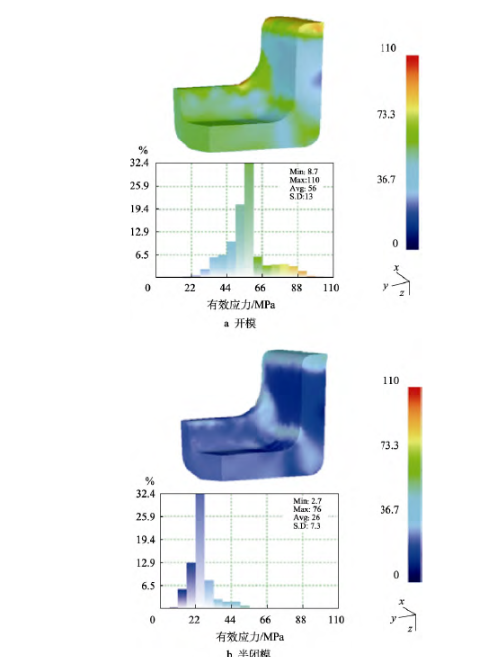

Li Lei et al. studied the process of punching and forming Mg-3Mn-0.5Ti-0.3V alloy, and found that the impact absorption work of magnesium alloy forgings was greatly affected by the reverse jacking force, edge pressing force and forging temperature, and the ideal punching and forging process was optimized as follows: forging at 380°C with 3.5kN edge pressing force and 4kN reverse jacking force. Zhang Hao et al. designed a split combination mold, and combined with finite element analysis software, the isothermal forging process of magnesium alloy gyroscope bracket was studied. In the punch downward stroke, the forming process is divided into five stages according to the flow deformation and filling of the metal. Through the reasonable shape of the blank and the design of the forming process, the gyroscope forgings were successfully forged. With the development of society, more and more requirements have been put forward for the forging and forming of metal materials, and the traditional forging process and mold design methods that mainly rely on experience have gradually lagged behind the times. At present, the use of finite elements and other related large-scale software to simulate the actual forging process has become a new research hotspot for simulation calculations on computers. Numerical simulation on the computer can save a lot of manpower and material resources, and complete the design of the forging forming process with the advantages of low cost and short cycle. Through modeling, the metal flow, stress field, strain field, temperature field, strain rate field, friction conditions, etc. in the forging process can be accurately calculated, the possible quality problems and defects can be predicted, and improvement or optimization methods can be proposed to improve the quality of forgings.Wang Shilei et al. used Pro/E software to three-dimensional forming of automobile disc hubs and molds, and analyzed and optimized the load conditions, temperature conditions and friction conditions in the forging process through finite element software, and modified the precision die forging process. Wang et al. studied the control measures of deformation uniformity and inner hole eccentricity of the actual mandrel forging by combining numerical simulation and experimental research, and proposed a symmetrical flip mandrel forging process to replace the existing sequential flipping process, which greatly improved the deformation uniformity. He et al. used finite element software to calculate the mold structure and forming parameters of the large AZ80 magnesium alloy support beam and experimentally formed it (as shown in Fig. 3).

Die forgings for large magnesium alloy support beams were produced by semi-closed dies and isothermal forging with multi-stage variable speeds. The microstructure of die forgings is small and evenly distributed, with excellent mechanical properties, and is used as helicopter components. Han Feng et al. simulated and analyzed the process of automobile wheel die forging, and found that increasing the corner radius of the upper die core can reduce the load and wear, and improve the service life of the upper die core. Rajive et al. used commercial software (ANSYS) to simulate the forging process on pan head bolts, discussed how to determine the stress distribution of asymmetrical sections in a forging die, and discussed the effect of these stresses on die wear and the flow characteristics of the forging. Deshak et al. used Deform 3D software to optimize the mold and blank sizes, reducing the load requirement from 1,600 tons to 539 tons. Wang et al. used Gleeble-3800 to perform thermophysical simulation compression of GH4066 alloy, established the material constitutive model, recrystallization model and grain growth model, and combined with finite element analysis, the forging process interval of the turbine disc was optimized. Chand et al. used finite element simulation to study the effective strain rate, effective stress, effective transformation, average die load, total energy dissipation and flow velocity distribution of sintered forged aluminum alloy preformed billet during the forming process, and the simulation results were consistent with the actual results. The development of national defense and military industry, civil automobiles and energy industries needs the support of advanced manufacturing technology, and the forging and forming of alloys in the future has the following development trends.1) Forging gradually develops from blank production to final part forming. Forging products are gradually becoming more precise and complex, which puts forward more stringent requirements for production process and quality control. It can be compensated forgedThe manufacturing system compensates and optimizes the elastic deformation in the production process, and combines the new process to form and manufacture parts with different uses and processing characteristics.2) Forging and forming are developing towards the trend of compounding with a variety of processing technologies, forming composite processes such as: upsetting + extrusion, multi-directional forging + die forging and other composite processes to meet the mechanical properties required by forgings and improve the quality of forgings.3) In terms of mold design and manufacturing, CAD/CAE/CAM and other technologies should be combined to shorten the mold research and development cycle, and at the same time, advanced mold processing technology should be applied to improve mold accuracy and surface qualityChoose the appropriate mold lubrication method to improve the quality of workpiece forming, carry out mold repair technology research, and improve the service life of the mold.4) The intellectualization of the production design and manufacturing process, the simulation and calculation of the forging process with the help of computer assistance, the corresponding modeling, algorithms, etc. are developed and optimized according to different application scenarios to improve the production and manufacturing efficiencyRate; Update forging equipment, improve the automation level of forging, shorten the material forming cycle, and reduce manufacturing costs; In addition to the traditional temperature field, stress field and strain field, the simulation of forging forming should also be combined with the microscopic structure field of the forging to optimize the structure of the forging, reduce the subsequent heat treatment process, achieve the purpose of reducing energy consumption, and realize the green and sustainable development of the forging industry.

Comments

Please Join Us to post.

0