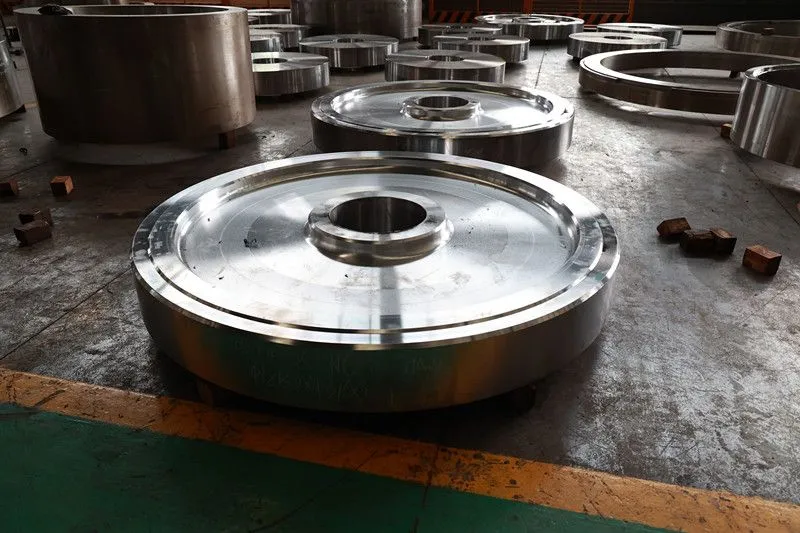

Ring forgings are a product of the forging industry and a type of forging. They are formed by applying external force to a metal billet (not sheet metal) through plastic deformation to achieve the desired compression force. This force is typically applied using a hammer or a press. The forging process creates a refined grain structure and improves the metal's physical properties. Ring forgings are a ubiquitous industrial product.

Production Process:

1. Wire Cutting: The steel ingot is cut into appropriate sizes and weights based on product requirements.

2. Heating (including tempering): The heating equipment primarily consists of single-chamber furnaces, pusher furnaces, and tabletop annealing furnaces. All furnaces use natural gas as fuel. The heating temperature of the steel ingot is generally between 1150°C and 1240°C. The heating time for cold steel ingots is approximately 1 to 5 hours, while the heating time for hot steel ingots is half that of cold steel ingots. After heating, the ingots enter the forging process.

3. Forging: The steel ingot, heated to approximately 1150-1240°C, is removed from the heating furnace and placed by an operator into an air or electro-hydraulic hammer. Depending on the size of the ingot and the required forging ratio, roughing and drawing processes are performed. The forging dimensions are monitored in real time, and the forging temperature is controlled using an infrared thermometer.

4. Inspection: The forging blank undergoes a preliminary inspection, primarily focusing on appearance and dimensions. Appearance is primarily inspected for defects such as cracks. Dimensions must ensure that the blank excess is within the drawing requirements, and records are kept.

5. Heat Treatment: A comprehensive process in which the forging is heated to a predetermined temperature, held at that temperature for a specified period, and then cooled at a predetermined rate to improve the internal structure and properties of the forging. This process aims to eliminate internal stresses, prevent deformation during machining, and adjust the hardness for easier machining. After heat treatment, the ingot is air- or water-cooled, and then quenched, depending on the material requirements.

Additional resources:

6. Rough Machining: After the forging is basically formed, it is processed into various specifications according to product requirements.

7. Ultrasonic Testing: After cooling, the forgings are cooled to approximately 20°C and then ultrasonically inspected to meet national standards I, II, and III, as well as for surface defects.

8. Mechanical Property Testing: To meet customer requirements, forgings must undergo mechanical property testing, primarily yield strength, tensile strength, and impact tests. Our main testing equipment currently includes one universal mechanical property testing machine, one impact testing machine, one continuous steel bar dotting machine, one ultrasonic flaw detector, one magnetic particle flaw detector, two thermometers, one electric double-blade broaching machine, one impact cryostat, one metallographic microscope, one metallographic pre-grinder, one metallographic cutting machine, and two Brinell hardness testers, which can basically meet the needs of routine testing for all types of forgings.

9. Final Inspection: Final inspection of finished forgings is performed to ensure that the forgings are smooth and free of defects such as cracks, and that their dimensions are within the drawing requirements. These inspections are then recorded.

10. Warehousing: After quality inspection, finished ring forging parts are simply packaged and stored in the finished product warehouse for shipment.

Comments

Please Join Us to post.

0